Design and Usage of Torch of Air Cooling C02 Welding(II)

2. The design of the torch

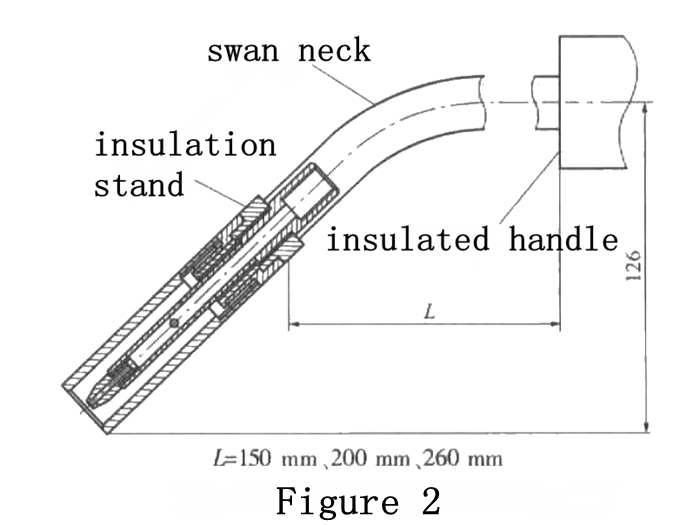

In the parts of the welding torch, the contact tips, the nozzle and the diffuser are the vulnerable parts and the standard parts. It is neither convenient nor economical to increase their sizes for the heat dissipation. As shown in Figure 2, there are 3 kinds of air-cooled automatic welding torches with length of 150mm, 200mm, 260mm. The length of swan necks are increased so that the welding torches have better cooling effect.

3.The usage of the torch

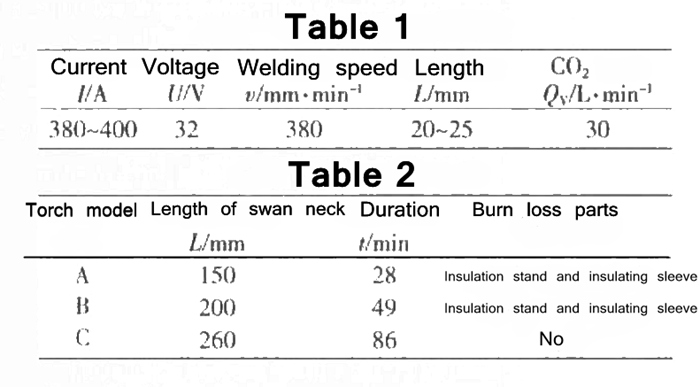

The air-cooled automatic welding torches with 3 swan neck length is tested by welding specification listed in Table 1. The result of trial welding is shown in Table 2. The welding torch models A, B and C represent different swan necks’ lengths of the welding torches with 150mm, 200Film and 260mm. It can be seen from table 2 that the increase of swan neck length can obviously improve the heat dissipation ability of the welding torch itself. When L>260mm, the welding torch can continuously weld about 1.5h at the current of 400A without firing the gun. The practical application of C welding torch in the automatic wheel welding machine and the automatic tongue welding machine has proved that the design has achieved the expected goal.

4.Conclusion

Under certain operating conditions and welding current conditions, the requirements of high current and long continuous welding can be met by increasing the heat dissipation capacity of the air cooled CO2 welding torch, so as to avoid the use of water cooled C02 welding torches.