MIG welding with aluminum requires special considerations to achieve optimal results. One crucial component in aluminum welding is the Teflon liner specifically designed for feeding aluminum welding wire. In this product classification introduction, we will explore the significance of Teflon liners for MIG welders, their role in aluminum welding, and how they enhance wire feeding efficiency.

A teflon liner for MIG welders, also known as a welding liner or wire liner for aluminum, is a flexible tube made from teflon (PTFE) material. It is designed to guide the aluminum welding wire from the wire feeder to the welding gun assembly. The Teflon liner's unique properties contribute to smooth wire feeding by reducing friction and preventing wire contamination.

When welding with aluminum, which has a softer and more delicate nature compared to other metals, using a Teflon liner becomes essential. Aluminum welding wires are often softer and more prone to tangling, bird-nesting, and wire feed issues. The Teflon liner's low-friction surface helps minimize resistance and friction, allowing the aluminum welding wire to glide smoothly through the liner, thus reducing the occurrence of wire feeding problems.

The teflon liner for MIG welders is specifically designed to enhance the wire feeding efficiency of aluminum welding applications. Aluminum welding wires are typically softer and more pliable, making them susceptible to bending or buckling during the feeding process. The Teflon liner's flexibility and non-stick properties help prevent kinks and tangles, ensuring a consistent and reliable wire feed.

MIG welders using aluminum welding wire can benefit from using a teflon liner designed specifically for aluminum applications. These liners are engineered to accommodate the diameter and characteristics of aluminum welding wire, ensuring optimal wire feeding performance. They help maintain a steady flow of wire, reducing the risk of wire jams, erratic feeding, and welding defects caused by inconsistent wire delivery.

When selecting a teflon liner for aluminum welding, it is important to consider compatibility with the MIG welder and the specific wire diameter. Manufacturers and suppliers offer teflon liners tailored for aluminum welding applications, providing welders with a reliable and efficient solution for achieving high-quality aluminum welds.

Teflon liners for MIG welders play a vital role in enhancing aluminum welding performance and wire feeding efficiency. By reducing friction, preventing wire tangles, and ensuring consistent wire delivery, these liners contribute to seamless and precise aluminum welds. Welders working with aluminum can benefit from investing in high-quality Teflon liners designed for aluminum welding applications, as they help optimize wire feeding and enhance overall welding results.

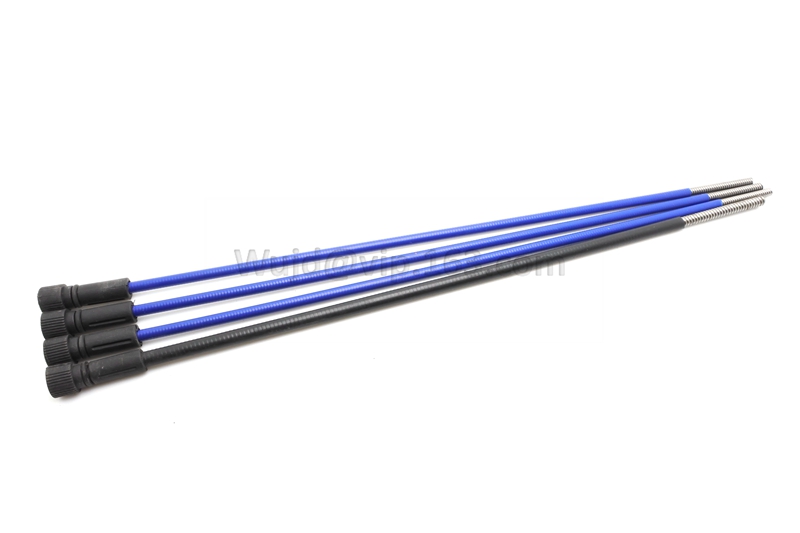

| Teflon Welding Liner for Aluminium Welding Wire |

| Material | Steel

|

| Blue Teflon liner | 1.0mm*3m 4.0/1.5 |

| Blue Teflon liner | 1.0mm*4m 4.0/1.5 |

| Blue Teflon liner | 1.0mm*5m 4.0/1.5 |

| Red Teflon liner | 1.0-1.2mm*3m 4.0/2.0

|

| Red Teflon liner | 1.0-1.2mm*4m 4.0/2.0 |

| Red Teflon liner | 1.0-1.2mm*5m 4.0/2.0 |

| Yellow Teflon liner | 1.6mm*3m 4.7/2.7 |

| Yellow Teflon liner | 1.6mm*4m 4.7/2.7 |

| Yellow Teflon liner | 1.6mm*5m 4.7/2.7 |

| Packing | 1piece or Roll Per Bag |

| Certification | ISO9001, CCC, CE, ROHS, TUV

|

● Available for Aluminum welding wire

● Wear-resisting

● Small friction

● Smooth delivery of welding wire

● Long usage life